We provide a solution during construction to prevent all finishing defects issues, helping customers make more with less through leaner processes. Satisfaction, peace of mind and cost saving.

BEBOND BBBONDER

- High Workability

- High water retention

- Easy to use

- Long open time

- Enhance cement strength

- Minimize cracks

- Reduced Shrinkage

- Better finishing

- Cost saving over conventional method

- Products to Prevent Plastering Hollowness

Product Description

BEBOND BBBONDER are particularly designed with high water withholding and enhances cement mortar tenacity and strength. It ensures increased workability and cost-effectiveness without compromising on the quality. Through its powerful adhesive properties, it helps in minimizing cracks and patches on the surfaces.

Cement Additives for Cost Saving

The significance of cement additives is not concealed from anyone. It is a widely acknowledged fact that can cement additives can rope in some amazing benefits during construction processes. They ensure increased workability, amplified compressive robustness, sturdiness, excellent finish as well as durability. There are many cement additives being openly sold in the market. But like everything else, they have classifications; some work better than the others and some work the best in these regards. We are here to let you about the right choice of Cement additive. We are here to tell you about the benefits/strength of “Bebond”.

What Makes Bebond Stand Out?

Apart from the other perks and benefits associated with the Bebond products, one thing that makes it strikingly different and better than the rest is the cost-effectiveness. The Bebond products, including the Cement Additives, massively help you in cutting down costs and extra expenditures related to various construction procedures. The Bebond additives help you save costs in so many ways. When you are using these products, it can save you a lot of bucks.

Usage

- Tiles installation (ceramic tiles, porcelain tiles, homogeneous tiles, marble, granite) for floor and wall

- Plastering

- Floor rendering and other cementitious products related activities such as cement floor patching, covering crack lines without hacking, wall cracks and hollow repair.

Advantages

- Suitable for all kind of surfaces

- High bonding, adhesion, tensile and flexural strength to unconventional plastering surfaces (withstand high vibration and movement)

- Suitable to bond various cementitious products such as plastering mortar, cement rendering, skim-coating and all cementitiuos screeds

- Minimize cracks

- Reduce shrinkage / shrink resistance (water resistance)

- Better finishing

- Time and cost saving over conventional method

- Excellent workability and simplicity - Apply with roller, no skilled worker needed

- Ready to use (No dilution or stirring needed)

Products to Prevent Plastering Hollowness

Are you looking for a reliable product to ward off plastering hollowness? Then read on, in this article we will tell you about some of the best products you can use to treat plastering hollowness.

What is the Problem?

It is often seen that after some years, the plaster on the walls starts coming off or losing its grip entirely. That can be really worrisome and frustrating, to say the least. When it continues for some time, a void starts amplifying within the wall and its plaster. Your walls become undulating and hollow or boxy sounding. They become disfigured and unappealing to behold.

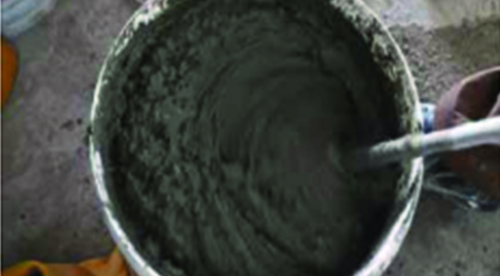

Mixing Steps

Step 1: Add 1 pack (100gm) of BEBOND BBBONDER with 25kg cement. Dry-mixed evenly.

Step 2: Prepare 7-8 liters of clean water.

Step 3: Pour pre-mixed cement into the water. (Additional mixing of up to 50% of fine sand is allowed)

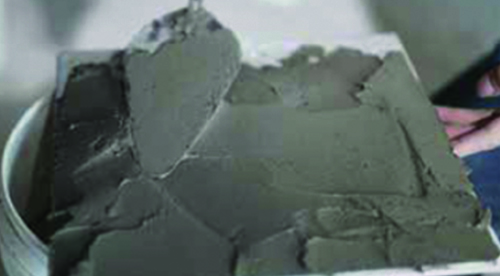

Step 4: Stir evenly until desired mortar paste is formed.

Step 5: Proceed with tilling works.

B) For plastering

Step 1: Add 1 pack (100gm) of BEBOND BBBONDER with 50kg cement + 250kg fine sand and water.

Step 2: Stir evenly until desired mortar paste formed.

Step 3: Proceed with plastering works.

Work Sequence

1. Add 1 pack (100gm) of BEBOND BBBONDER / 1 pack (100gm) of BEBOND BBBONDER PLUS into 7-8 liters of clean water and stir.

2. Pour 25kg cement into water and stir evenly. (Additional mixing of up 40% of fine sand is allowed)

3. Apply ready mixed grout (BEBOND BBBONDER / BEBOND BBBONDER PLUS + water + cement) to the tile treated with BEBOND BB1.

4. Direct tilling on substrate treated with BEBOND BBPRIME.

1) RECOMMENDED WORK SEQUENCE FOR DIRECT TILING ON RC/LIGHTWEIGHT/CEMBOARD/CONCRETE FLOOR

Substrate : Apply BEBOND BBPRIME

Bedding : BEBOND BBBONDER + Cement + Sand

Rear Side of Tile : Apply BEBOND BB1

2) RECOMMENDED WORK SEQUENCE FOR TILING ON PLASTERED WALL/CEMENT RENDERED FLOOR

Substrate : Nil

Bedding : BEBOND BBBONDER + Cement + Sand

Rear Side of Tile : Apply BEBOND BB1

3) RECOMMENDED WORK SEQUENCE FOR TILE OVER TILE/TILE OVER EPOXY SURFACE

Substrate : Apply BEBOND BB1

Bedding : BEBOND BBBONDER + Cement + Sand

Rear Side of Tile : Apply BEBOND BB1